What Does Bayside Laser Mean?

Wiki Article

The Best Strategy To Use For Bayside Laser

Table of ContentsBayside Laser for BeginnersBayside Laser Can Be Fun For AnyoneNot known Facts About Bayside LaserThe Ultimate Guide To Bayside LaserExcitement About Bayside LaserThe Best Guide To Bayside Laser

Traveling optic machines have to utilize some method to consider the changing light beam length from the close to area (close to the resonator) cutting to the far area (away from the resonator) cutting. Common techniques for regulating this include collimation, adaptive optics, or the usage of a constant beam of light size axis.

The power intake as well as performance of any specific laser will certainly vary depending upon result power and operating criteria. This will depend upon the sort of laser and also how well the laser is matched to the job at hand. The quantity of laser cutting power required, referred to as heat input, for a specific work depends upon the material type, thickness, process (reactive/inert) made use of, and also desired cutting price.

Some Of Bayside Laser

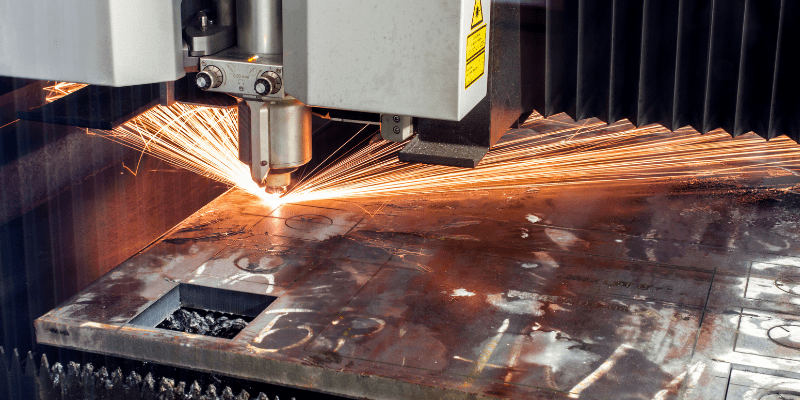

Making use of computerised systems allows for accurate and complex shapes that would have been impossible with traditional cutting (steel laser cutting). The user can conveniently control the cut's depth by adjusting the laser light beam's power and also focus. Laser cutting is common in steel, timber, plastics and also textiles. However it likewise has applications for engraving, etching and also noting.Whether you're searching for a new or upgrading your procedures, laser cutting has large applications, particularly in manufacturing. That claimed, below are 4 advantages of laser cutting: Laser reducing is just one of one of the most advanced, precise and also precise methods for reducing products. It can offer a degree of information and precision that hand devices can never get to.

Not known Facts About Bayside Laser

The capacity for laser cutting seems almost infinite as it provides businesses high-grade common outcomes in a portion of the time. Laser-cutting modern technology is flexible and also suitable with numerous products, ranging from wood as well as leather to even more difficult-to-cut steels. For these harder-to-cut materials, laser cutters develop excellent accuracy cuts that are not available with traditional cutting devices.Laser-cutting devices are as straightforward as many devices goes. Still, below are four ideas to assist get the most out of your process: With laser cutting, choosing the appropriate product for the work is vital. Depending on the designated application, various materials may be better than others depending upon elements such as durability as well as safety and security.

Some Known Factual Statements About Bayside Laser

Clearly, laser cutting is a whole lot faster than the traditional approach of reducing metal, yet is it faster than other contemporary methods? Laser cutting beats thermal cutting approaches such as plasma or flame in rate when reducing metal of up to 10mm thick.For those that need to reduce great deals of various shapes, laser cutting is certainly the most attractive steel reducing option. With this technique of reducing metal, you do not require to transform tools to alter cuts as the specific same arrangement will certainly execute numerous reducing tasks as visit long as the density continues to be the very same.

During the laser reducing procedure, the beam used does not really need to touch the material that is being cut, resulting in less danger of damage. This suggests that you will not require to incur pricey repairs or delayed completion times as you could with other methods of reducing steel - cnc cutting service.

The Definitive Guide to Bayside Laser

Laser reducing needs much less power than various other techniques, making use of generally 10k, W of power contrasted to 50k, W for various other reducing procedures. Naturally, the safety and security of your employees is always at the leading edge of your mind and also laser reducing offers among the most safe methods of reducing metal.That accurate factor produces an incredibly high strength that can cut via the product. The entire process is controlled by, you guessed it, a computer. Yet, behind that computer is frequently a qualified specialist that aids direct the procedure so everything runs smoothly. Contrasted to conventional reducing methods, laser reducing deals several benefits.

Unlike several producing machines, laser cutters typically do not need you to change out various tools for whatever cut you want. Laser cuttings use extreme precision compared to various other standard cutting approaches.

Getting My Bayside Laser To Work

Relying on exactly how a laser cutter is established up, you're frequently mosting likely to observe possibly a small burr on a component. Usually, it's not needed to get rid of the burr, but it depends upon the product, its thickness and various other variables. Oh yes, this is one of the finest components of making use of a laser cutter; flexibility.

No task is also complicated for the laser cutter. An extremely slim area of product is easily navigated by the high-powered laser as well as is really hardly ever warped or distorted. Jobs are not just restricted to sheet steel with a laser cutter. Lasers have the capacity to reduce stainless-steel, light weight aluminum, copper, and brass.

Report this wiki page